Laser Welding Machine Solutions Revolutionizing the Automotive Industry

Introduction:

In recent years, the automotive industry has witnessed

significant advancements in manufacturing processes, leading to increased

efficiency, precision, and cost-effectiveness. Among the various cutting-edge

technologies that have emerged, laser welding machines have proven to be a

game-changer. Laser welding offers numerous advantages over traditional welding

methods, making it the preferred choice for automotive manufacturers looking to

enhance their production capabilities. In this blog, we will explore the

benefits of laser welding, the leading manufacturers in the industry, the

associated costs, and its applications in the automotive sector.

Advantages of Laser

Welding Machines:

1. Enhanced Precision:

Laser welding machines provide exceptionally precise and accurate welds, resulting in superior joint quality. The focused laser beam allows for narrow, deep welds with minimal heat-affected zones, reducing the risk of distortion or damage to surrounding components.

2.Increased Productivity:

Laser welding significantly improves manufacturing efficiency by enabling faster welding speeds and cycle times. The automated nature of laser welding machines, combined with their ability to produce consistent welds, minimizes the need for manual intervention and rework, leading to higher throughput.

3.Versatility in Materials:

Laser welding machines can handle a wide range of automotive materials, including steel, aluminum, and various alloys. This flexibility allows manufacturers to adapt to different vehicle designs and production requirements seamlessly.

4. Cost-Effectiveness:

While

the initial investment in laser welding technology may be higher than

traditional welding methods, the long-term cost benefits are substantial. Laser

welding reduces material waste, lowers labor costs, and minimizes post-welding

processes such as grinding and finishing, ultimately improving the overall

profitability of automotive manufacturing.

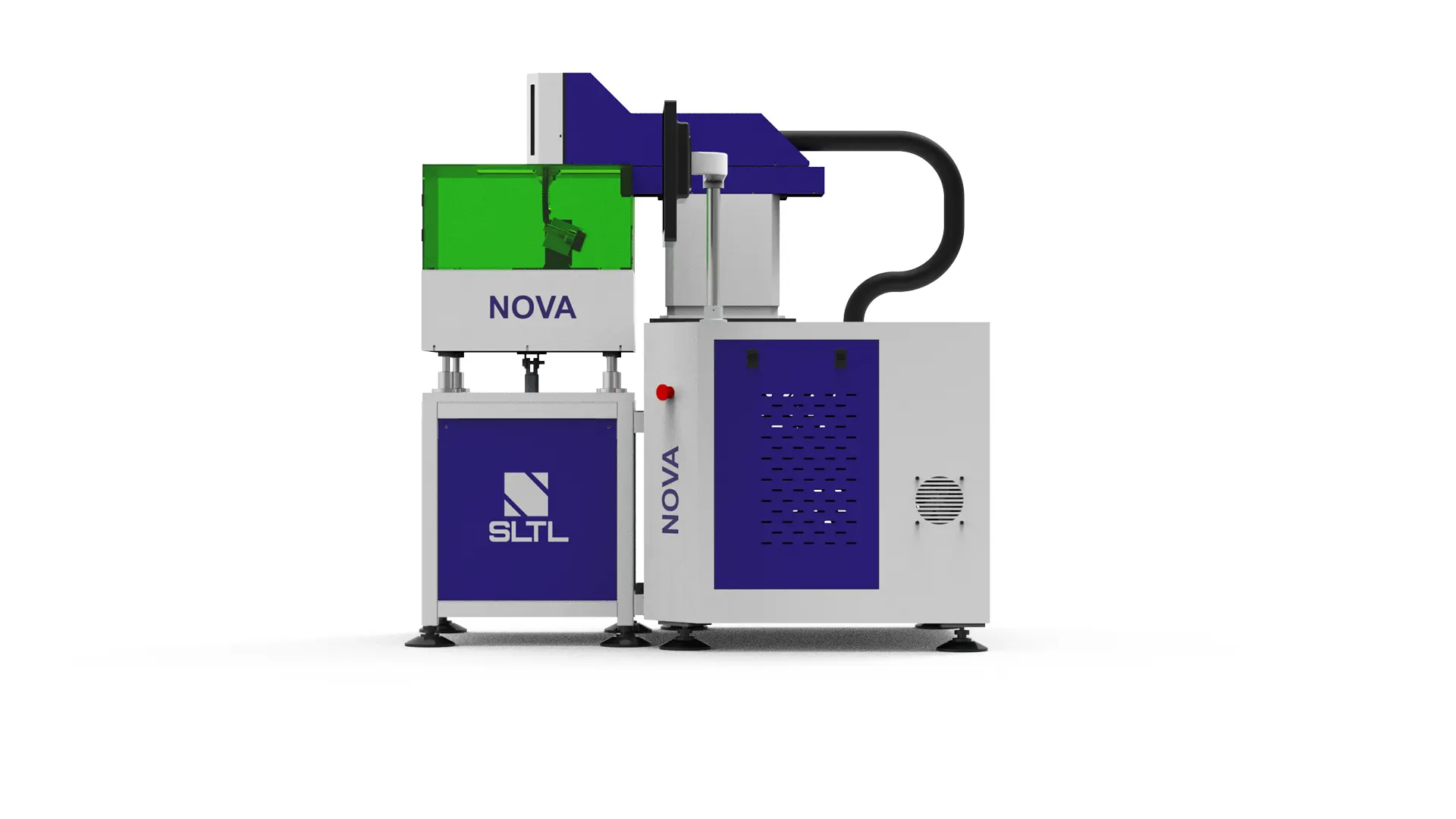

Leading Laser Welding Machine Manufacturers:

2.

Trumpf: Trumpf is a renowned manufacturer of

laser welding machines with a strong presence in the automotive industry. Their

products are known for their precision, reliability, and innovative features,

offering a comprehensive range of solutions tailored to specific manufacturing

needs.

Cost of Laser Welding Systems:

Applications in the Automotive Industry:

Laser

welding machines find extensive use in various automotive applications,

including:

1. 1.Body-in-White (BIW) Assembly: Laser welding ensures precise and robust joining of automotive body structures, reducing weight, improving structural integrity, and enhancing safety.

2. Battery Manufacturing: Laser welding is crucial for assembling battery cells and modules in electric vehicles. It provides efficient and reliable welding of dissimilar materials and enables high-speed production.

3.Exhaust Systems: Laser welding ensures leak-free and durable welds in exhaust systems, contributing to enhanced performance and reduced emissions

4.Powertrain Components: Laser welding is used in the fabrication of engine components, transmission systems, and fuel injection systems, ensuring reliable and efficient operation.

Conclusion:

The applications of laser welding in the automotive industry

are diverse, ranging from body-in-white assembly and battery manufacturing to

exhaust systems and powertrain components. Laser welding ensures precise and

robust joining, contributing to lighter and safer vehicles, efficient electric

powertrains, and improved performance.

In conclusion, laser welding machines offer a multitude of

advantages that make them indispensable in the automotive industry. As

automotive manufacturers strive for increased manufacturing capabilities, laser

welding technology will continue to play a vital role in shaping the future of

automotive production, fostering innovation, and driving the industry towards

excellence.

.jpg)

Comments

Post a Comment